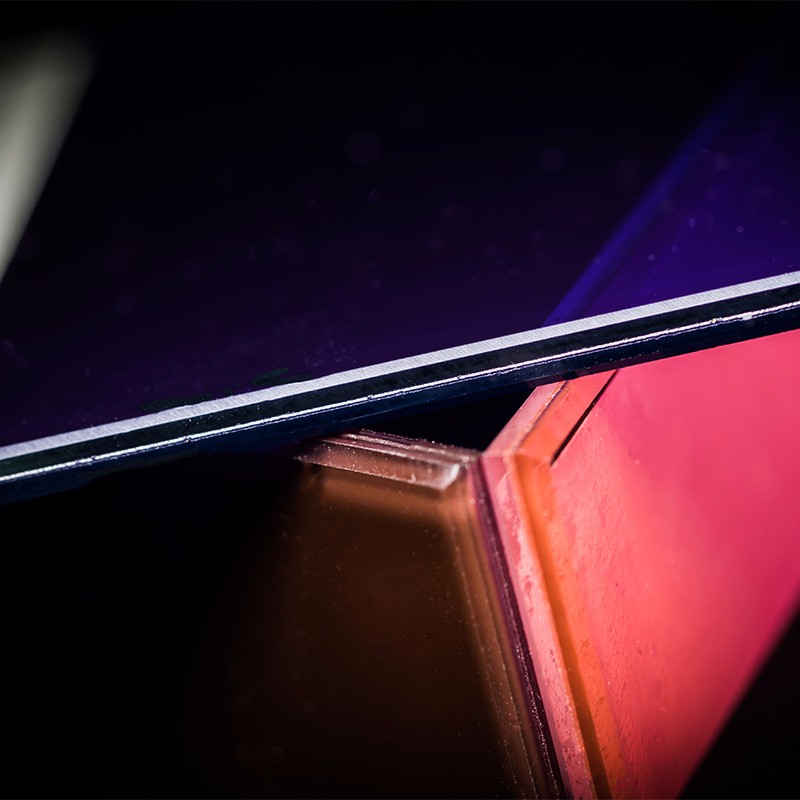

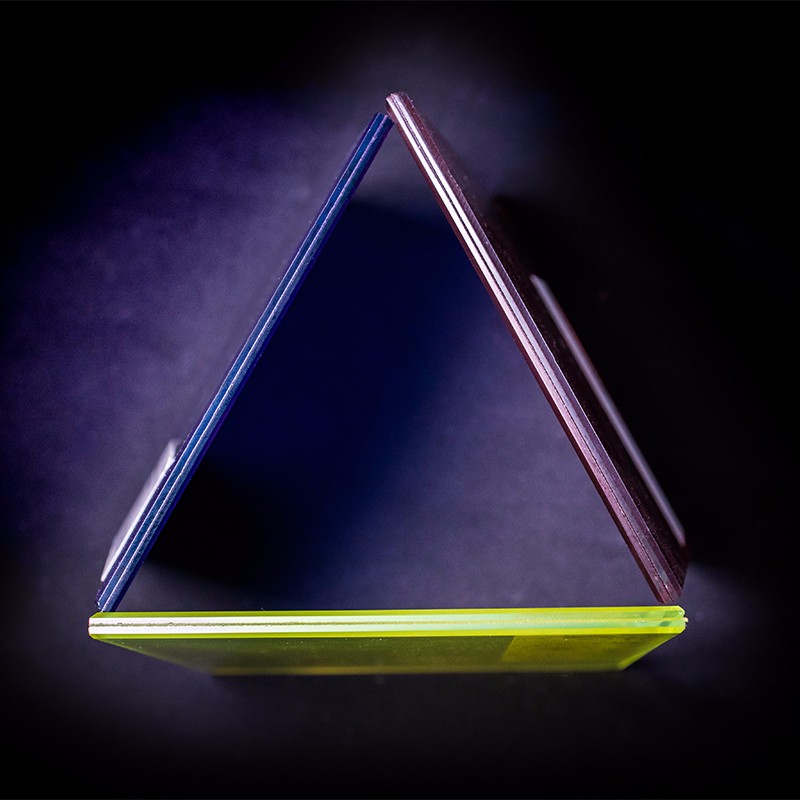

Laminated glass

The laminated glass is a kind of advanced safety glass, and binding material PVB (polyvinyl butyral) or EVA (vinyl acetate polymer) middle film and SGP film are bonded in two or more glasses, and then being heated and pressed with high temperature and pressure to form the advanced safety glass.

● characteristics:

◆Safety: The laminated glass installed in the building can still keep intact in the original frame after being suffered any external shocks, even if glasses broken. Personnel inside and outside the building will not be hurt by flying shards of glass;

◆Anti hurricane and earthquake: it cannot fall to ground and can remain in situ even if glasses broken.

◆blast and ballistic protection: multilayer laminated glass can be used to create multiple levels of bullet-proof glasses;

◆UV protection: have great barrier effect for sunlight's ultraviolet rays; UV Rejection is up to 99%; can avoid ultraviolet radiation;

◆Noise-reduction performance: PVB film has insulation and absorption effects for sound wave, so that it can reduce noise.

● Quality standard

◆Laminated glass quality is in accordance with GB15763.3-2009 of national standard;

◆Laminated glass has passed the Architectural Safety Glass of Australian Standard--AS/NZS2208-1996 (the highest standard requirement in the world) and simultaneously meets ANSIZ97.1-2004.

● Process specification:

◆Producing thickness: 5mm~60mm

◆Maximum size: 2440mm*6000mm

● Annual production capacity

500,000.00 m2

- PreviousPaint glass

- NextGreen mirror